Product Introduction

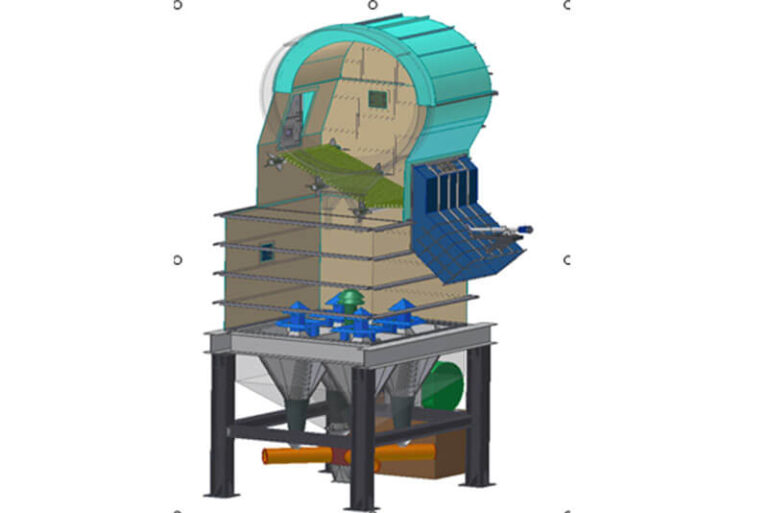

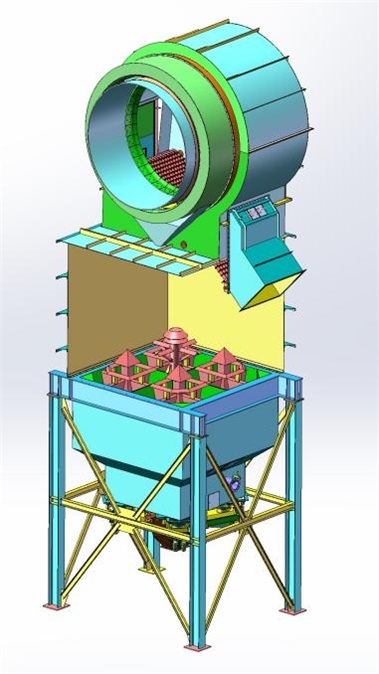

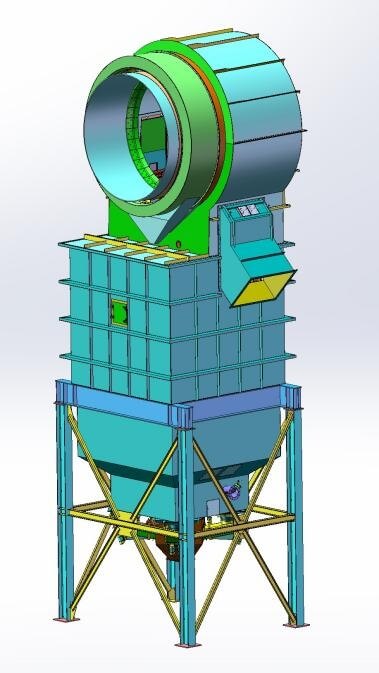

The high-temperature block materials discharged from the kiln head fall into the vertical cooler, which is first set in the upper part. The heat-resistant grate plate discharges the large pieces of materials or kiln skins sintered in the kiln to the outside of the cooler through the large piece discharge mechanism. Normal materials fall from the gap in the middle of the heat-resistant grate plate into the top of the hood and accumulate. The normal temperature air blown in by the secondary air fan distributes the cooling air to the twin tower center hoods and the twin tower split hoods through the secondary air duct and air distribution valve. The normal temperature cooling air is blown through the hoods into the high-temperature materials accumulated on the top for heat exchange. The heated materials are discharged to the conveying equipment through the vibrating feeder set at the bottom and transported away. The secondary air is heated to above 650°C and enters the kiln to participate in combustion.

The complete set of equipment consists of kiln head cover, cooler body, support frame, heat-resistant grate plate, large block discharge mechanism, twin-tower center hood, twin-tower split hood, vibrating feeder, secondary air duct, air distribution valve, collection, dust air duct and other parts.

Product Advantages

01.

The cooling hood adopts a double-tower design, which greatly improves the cooling effect and shortens the cooling time.

02.

The hood is made of ZG40Gr25Ni20Si2 material, which improves the heat resistance temperature and extends the service life.

03.

The unique air duct design makes the cooling air distribution more reasonable and the cooling more uniform.

04.

The discharging vibrating feeder set at the bottom adopts a double-hanging design, which is safer to use, more stable in discharging materials, easier to collect dust, and more environmental protection.

Application Scope

The SL.LQ vertical cooler is a cooling device matched with the rotary kiln. It is suitable for cooling limestone, dolomite, manganese ore and other massive materials after calcined in the rotary kiln.

Main Technical Specifications

| Model | Capacity(T/D) | Cross-sectional Area(m2) | Grain Size(mm) | Feeding Temp.(℃) | Discharge Temp.(℃) | Cooler Pressure Loss(Pa) | Vibrating Feeder | ||

| Capacity(t/h) | Qty’(set) | Unit Power(kw) | |||||||

| SL.LQ3.5×3.5 | 200 | 8.6 | 10~50 | 1100±50 | ≤80+Ambient Temp. | ≤5000 | 15 | 4 | 2×0.25Frequency |

| SL.LQ3.5×3.5 | 300 | 8.6 | |||||||

| SL.LQ3.8×3.8 | 400 | 10.5 | |||||||

| SL.LQ4.0×4.0 | 600 | 11.8 | |||||||

| SL.LQ4.7×4.7 | 800 | 17.1 | |||||||

| SL.LQ5.2×5.2 | 1000 | 21.5 | |||||||

| SL.LQ5.4×5.4 | 1200 | 23.4 | |||||||