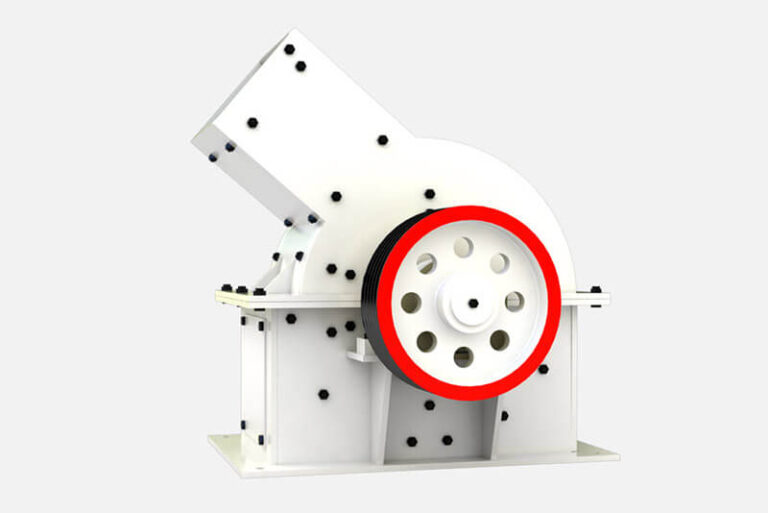

Product Introduction

The hammer crusher is mainly composed of a box body, a rotor, a hammer head, an impact lining plate, a screen plate, etc. When the hammer crusher is working, the motor drives the rotor to rotate at high speed, and the materials enter the crusher cavity evenly. The high-speed rotating hammer head impacts, shears, and tears the materials, causing them to be broken.

At the same time, the gravity of the material itself causes the material to rush from the high-speed rotating hammer head to the baffle and screen bars in the frame. Materials larger than the screen hole size are retained on the screen plate and continue to be hit and ground by the hammer until they are broken to the required size. The discharging granularity is finally discharged out of the machine through the sieve plate.

Product Advantages

01.

The overall design is perfect, the structure is simple and compact;

02.

One-time feeding and molding, large crushing ratio and high production efficiency;

03.

Wear-resistant and impact-resistant, with few wearing parts, easy maintenance, energy saving and environmental protection.

Application Scope

The application scope of hammer crusher is mining, smelting, building materials, highways, railways, water conservancy and chemical industries, etc. It is suitable for materials such as granite, basalt, limestone, river pebbles, cement clinker, quartz stone, iron ore, bauxite, Construction waste, salt, bricks, coal, etc.

Main Technical Specifications

| Model | Capacity (t³/h) | Motor Power (kw) |

| PCΦ400×300 | 3-10 | 4P 11 |

| PCΦ600×400 | 6-22 | 4P 22 |

| PCΦ800×600 | 10-40 | 4P 55 |

| PCΦ1000×800 | 15-50 | 4P 75 |

| PCΦ1000×1000 | 18-55 | 4P 90 |