Product Introduction

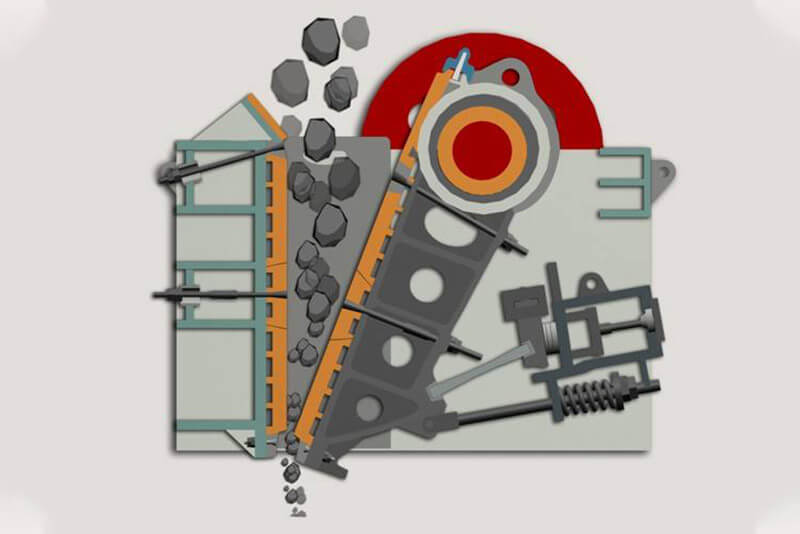

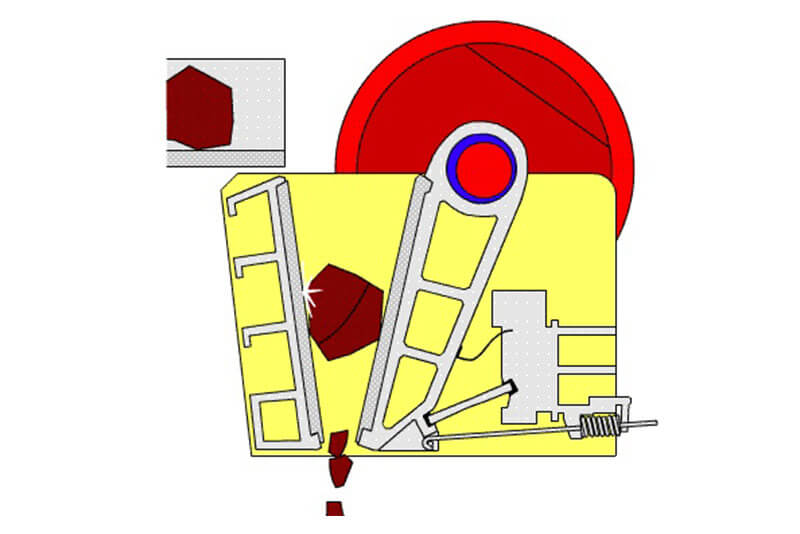

Jaw crusher is mainly composed of frame, eccentric shaft, large pulley, flywheel, side guard plate, toggle plate, toggle plate rear seat, gap adjustment screw, return spring, fixed jaw plate and movable jaw plate.

The crushing method of jaw crusher is curved extrusion type. When working, the motor drives the belt and pulley, and moves the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thus pushing the movable jaw plate closer to the fixed jaw plate, and the material passes through the two jaws. Multiple crushing is achieved by squeezing, rubbing, grinding, etc. between the plates; when the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring, and the crushed materials Under the action of gravity, it is discharged freely through the discharge port at the lower part of the jaw cavity. With the continuous rotation of the motor, the movable jaw performs periodic crushing and discharge to achieve mass production.

Product Advantages

01.

A heavy guard plate is installed above the movable jaw to withstand the strong impact of materials;

02.

Made of high manganese steel, gray cast iron and high-strength forged steel, with sufficient stiffness and strength;

03.

Equipped with an overload protection mechanism to prevent damage to the equipment;

04.

Centralized lubrication system, easy to operate and maintain, long service life, saving replacement costs.

Application Scope

The application range of jaw crusher is sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc. It is suitable for materials such as river pebbles, granite, basalt, iron ore, limestone, quartz stone, diabase, iron ore, gold ore, copper ore, etc.

Main Technical Specifications

| Model | Inlet Grain Size (mm) | Feed Grain Size (mm) | Discharge Grain Size (mm) | Capacity (t/h) | Power (kw) | Overall Dimensions (mm) |

| PE1500×1800 | 1500×1800 | ≤1200 | 210-360 | 520-1100 | 280 | 7460×6235×4249 |

| PE1200×1500 | 1200×1500 | ≤1020 | 150-300 | 400-800 | 160-220 | 6380×5310×3710 |

| PE1000×1200 | 1000×1200 | ≤850 | 200-300 | 280-560 | 110-160 | 5350×4280×3050 |

| PE900×1200 | 900×1200 | ≤750 | 95-165 | 220-450 | 110-132 | 3800×3166×3045 |

| PE750×1060 | 750×1060 | ≤630 | 80-140 | 110-320 | 90-110 | 2655×2302×3110 |

| PE600×900 | 600×900 | ≤480 | 65-160 | 90-180 | 55-75 | 2290×2206×2370 |

| PE500×750 | 500×750 | ≤425 | 50-100 | 40-110 | 45-55 | 2035×1921×2000 |

| PE400×600 | 400×600 | ≤350 | 40-100 | 15-60 | 30-37 | 1700×1732×1653 |

| PE250×400 | 400×250 | ≤200 | 20-50 | 5-20 | 15 | 1430×1310×1340 |

| PEX300×1300 | 300×1300 | ≤250 | 20-90 | 30-90 | 55-75 | 1750×2320×1724 |

| PEX250×1200 | 250×1200 | ≤210 | 25-60 | 20-60 | 37-45 | 2192×1900×1950 |

| PEX250×1000 | 250×1000 | ≤210 | 25-60 | 15-50 | 30-37 | 1550×1964×1380 |

| PEX250×750 | 250×750 | ≤210 | 25-60 | 15-30 | 22-30 | 1667×1545×1020 |

| PEX150×750 | 150×750 | ≤125 | 18-48 | 5-16 | 15 | 1200×1500×1200 |

| PEX150×250 | 150×250 | ≤125 | 10-40 | 1-3 | 5.5 | 896×745×935 |