Product Introduction

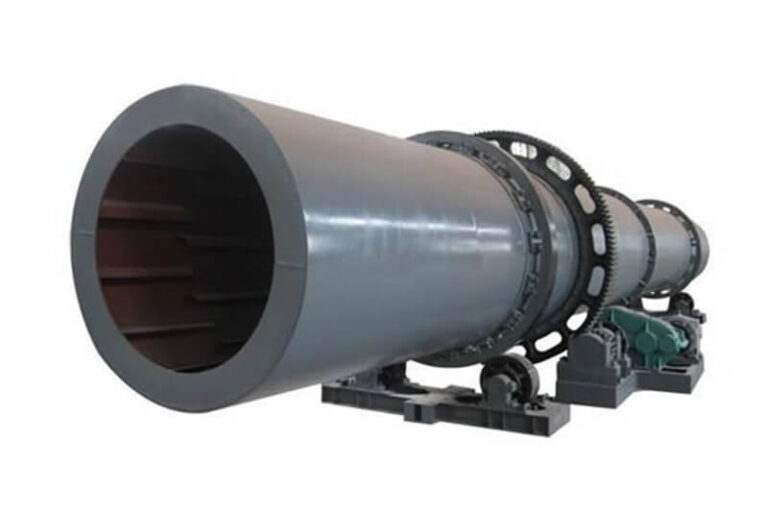

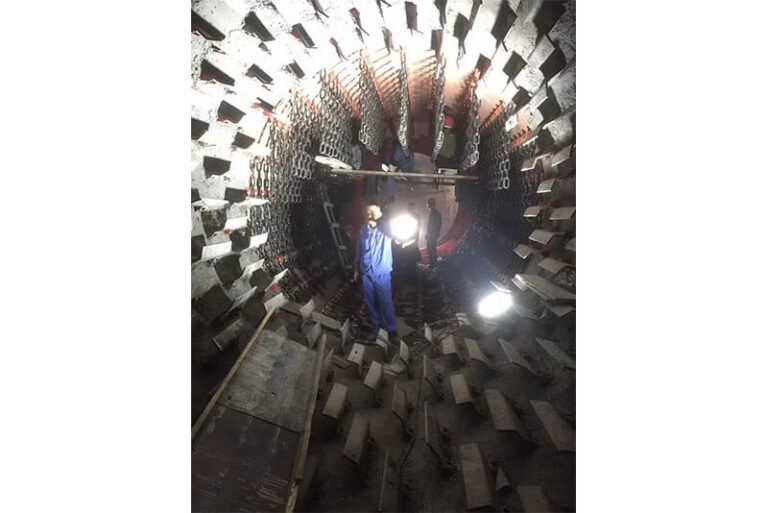

The rotary dryer is mainly composed of a rotary body, a baffle, a transmission device, a support device and other components. Its working principle is: Utilize the lifting plates that are reasonably arranged and evenly distributed in the cylinder with alternating angles to throw the water-containing materials into the rotating cylinder. The water is secreted from the materials through the hot air flow and turns into water vapor and is discharged into the atmosphere. medium and dry.

Product Advantages

01.

The rotary dryer has a larger drying capacity;

02.

Larger production capacity and higher operating rate;

03.

Better smooth and reliable operation;

04.

Energy saving, environmental protection, easier operation and maintenance, etc.

Application Scope

Rotary dryers are widely used for drying slag, clay, limestone and other materials in cement, chemical, metallurgy, building materials and other industries.

Main Technical Specifications

| Dimension(m) | Diameter(mm) | Length(mm) | Capacity(t/h) | Rotating Speed(r/min) | Inclination(%) | Motor Type | Power(kw) | Reducer Model |

| Ф1.5×12 | Ф1500 | 12000 | 6-9 | 1.4-7 | 5 | YCT-225-4B | 15 | JZQ500 |

| Ф1.5×14 | Ф1500 | 14000 | 7-10 | 1.4-7 | 5 | YCT-225-4B | 15 | JZQ650 |

| Ф1.6×14 | Ф1600 | 14000 | 8-11 | 1.4-7 | 5 | YCT-225-4B | 15 | JZQ650 |

| Ф1.8×14 | Ф1800 | 14000 | 9-13 | 3.5-6.5 | 5 | YCT-225-4B | 15 | JZQ650 |

| Ф2.0×14 | Ф2000 | 14000 | 11-16 | 2.2-7.4 | 5 | YCT-250-4A | 18.5 | JZQ750 |

| Ф2.2×12 | Ф2200 | 12000 | 12-17 | 2.2-7.4 | 5 | YCT-250-4B | 22 | JZQ750 |

| Ф2.2×14 | Ф2200 | 14000 | 14-20 | 2.2-7.4 | 5 | YCT-250-4B | 22 | JZQ750 |

| Ф2.4×18 | Ф2400 | 18000 | 21-31 | 2.2-7.4 | 4 | YCT-280-4A | 30 | JZQ850 |

| Ф2.4×20 | Ф2400 | 20000 | 23-34 | 2.2-7.4 | 4 | YCT-315-4A | 37 | JZQ850 |

| Ф2.4×22 | Ф2400 | 22000 | 26-38 | 2.2-7.4 | 4 | YCT-315-4A | 37 | JZQ850 |

| Ф2.6×20 | Ф2600 | 20000 | 28-40 | 2.2-7.4 | 4 | YCT-315-4B | 45 | ZQ100 |

| Ф2.6×24 | Ф2600 | 24000 | 33-48 | 2.2-7.4 | 4 | YCT-315-4B | 45 | ZQ100 |

| Ф3.0×20 | Ф3000 | 20000 | 35-54 | 8.4-3.85 | 4 | YCT-355-4A | 55 | ZL100 |

| Ф3.0×25 | Ф3000 | 25000 | 46-64 | 8.4-3.85 | 4 | YCT-355-4B | 75 | ZL100 |

| Ф3.0×28 | Ф3000 | 28000 | 52-74 | 8.4-3.85 | 4 | YCT-355-4B | 75 | ZL100 |

| Ф3.2×25 | Ф3200 | 25000 | 60-80 | 2.4-7.6 | 4 | YCT-355-4C | 90 | ZL115 |

| Ф3.4×40 | Ф3400 | 40000 | 100-120 | 4.16 | 3.5 | Y315L2-4 | 200 | ZSY500-45-Ⅱ |

| Ф3.6×32 | Ф3600 | 32000 | 130-140 | 5.01 | 3.5 | YTP315L2-4 | 200 | YNS995-35.5-VBL |

| Ф4×36 | Ф4000 | 36000 | 45 | 5.01 | 3.5 | Y355M2-4 | 250 | ESY500-35.5-Ⅱ |

| Ф4.3×34 | Ф4300 | 34000 | By Process | 3.24 | 5 | YSNP400L2-6 | 315 | ZSY560 |

| Ф4.4×40 | Ф4400 | 40000 | By Process | 3.6 | 5 | YSNP450L2-6 | 400 | ZSY630 |

| Ф5×45 | Ф5000 | 45000 | By Process | 3.2 | 5 | YSNP500L3-6 | 710 | JH800C-28 |