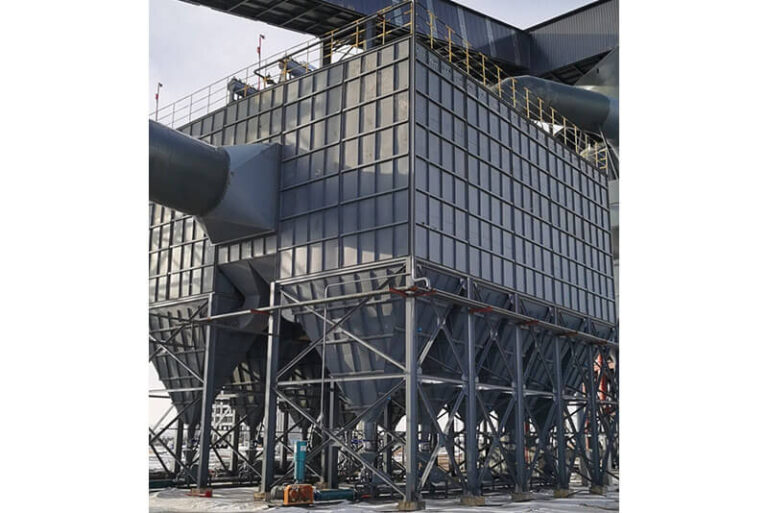

Product Introduction

The filter bag is made of textile filter cloth or non-textile felt. The filtering effect of fiber fabric is used to filter dust-containing gas. When the dust-containing gas enters the bag dust collector, the dust with large particles and heavy specific gravity will be removed due to gravity. It will settle down and fall into the ash hopper. When the gas containing fine dust passes through the filter material, the dust is blocked, thus the gas can be purified.

Product Advantages

01.

Module production and unit combination. Separate chamber offline pulse jet dust cleaning technology has strong dust cleaning capacity, high dust removal efficiency, low emission concentration, low air leakage efficiency, low energy consumption, low steel consumption, small floor space, stable and reliable operation, and good economic benefits;

02.

Adopting the design concept of large air volume and low wind speed, the dust collector has low resistance;

03.

A reasonable air flow secondary distribution method is adopted to improve the utilization rate of the filter area and the service life of the filter material;

04.

The filter bag adopts a vertical and horizontal matrix arrangement, which has a compact structure and high space utilization. The upper end of the filter bag adopts a spring expansion ring form, which has good sealing performance and quick bag change.

Application Scope

Pulse single-machine bag dust collector is widely used in dust removal of industrial silicon production, pharmaceutical, stone plant, asphalt mixing station, coal-fired boiler plant, cement plant, lime plant, steel plant, coal washing plant, chemical fertilizer factory, bio-boiler factory, and other building materials, metallurgy, machinery, chemical and refractory materials industries.

Main Technical Specifications

| JQM-32 | JQM-48 | JQM-64 | JQM-80 | JQM-96 | JQM-112 | ||

| Processing Air Volume(m3/h) | 1500-2100 | 2100-3200 | 2900-4300 | 4000-6000 | 5200-7000 | 6000-9000 | |

| Total Filter Area(m3/h) | 24 | 36 | 48 | 60 | 72 | 84 | |

| Filter Wind Speed(m/min) | 1.0-1.5 | 1.0-1.5 | 1.0-1.5 | 1.1-1.7 | 1.2-1.7 | 1.2-1.8 | |

| Filter Bag No. | 32 | 48 | 64 | 80 | 96 | 112 | |

| Inlet Gas Temp.(℃) | ≤120℃ | ||||||

| Equipment Resistance(Pa) | ≤1200 | ||||||

| Inlet Dust Concentrationln (g/m3) | <200 | ||||||

| Outlet Emission Concentration (mg/m3) | ≤50 | ||||||

| Dust Cleaning Compressed Air | Pressure (mpa) | 0.5-0.7 | |||||

| Compressed Air (m3/min) | 0.10 | 0.14 | 0.20 | 0.24 | 0.29 | 0.34 | |

| Negative Pressure (Pa) | 5000 | ||||||

| Pulse Valve Quantity | 4 | 6 | 8 | 10 | 12 | 14 | |

| Fan/Motor Power (kw) | 1.5 | 3.0 | 3.0 | 5.5 | 5.5 | 7.5 | |