Product Introduction

Rotary kiln refers to a rotating calcining kiln, which belongs to the category of building materials equipment. Rotary kilns can be divided into cement kilns, metallurgical chemical kilns and lime kilns according to different processed materials.

Cement kilns are mainly used for calcining cement clinker and are divided into two categories: dry production cement kilns and wet production cement kilns. The metallurgical chemical kiln is mainly used in the metallurgical industry for magnetization and roasting of lean iron ore in steel plants; oxidation roasting of chromium and nickel iron ore; high-alumina bauxite roasting in refractory materials plants and aluminum hydroxide roasting of clinker in aluminum plants. Chemical plants use rotary kilns to roast chromium ore and chromium ore powder and other similar minerals. Lime rotary kiln is used for roasting activated lime and light burnt dolomite used in steel plants and ferroalloy plants.

Product Advantages

01.

The rotation speed is flexible, and the transmission device makes the cylinder rotate at the required speed through the ring gear located in the middle of the cylinder;

02.

Easy installation and maintenance. Larger kilns are equipped with an auxiliary transmission device that allows the cylinder to rotate at a very low speed to meet the needs of installation and maintenance.

Application Scope

Suitable for metallurgy, building materials, chemical industry, lime, cement and other related industry.

Main Technical Specifications

| Model | Diameter/m | Length/m | Slope/% | Capacity(t/d) | Rotating Speed | Motor Powder/kw |

| Φ2.5x40m | 2.5 | 40 | 3.6 | 180 | 0.44-2.44 | 55 |

| Φ2.5x50m | 2.5 | 50 | 3.0 | 200 | 0.62-1.86 | 55 |

| Φ2.5x54m | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 |

| Φ2.7x42m | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 |

| Φ2.8x44m | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 |

| Φ3.0x45m | 3.0 | 45 | 3.5 | 500 | 0.5-2.47 | 75 |

| Φ3.0x48m | 3.0 | 48 | 3.5 | 700 | 0.6-3.48 | 100 |

| Φ3.0x60m | 3.0 | 60 | 3.5 | 800 | 0.3-2.0 | 100 |

| Φ3.2x50m | 3.5 | 50 | 4.0 | 1000 | 0.6-3.0 | 125 |

| Φ3.3x52m | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 |

| Φ3.5x54m | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 |

| Φ3.6x70m | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 |

| Φ4.0x56m | 4.0 | 56 | 4.0 | 2300 | 0.41-4.07 | 315 |

| Φ4.0x60m | 4.0 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 |

| Φ4.2x60m | 4.2 | 60 | 4.0 | 2750 | 0.41-4.07 | 375 |

| Φ4.3x60m | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 |

| Φ4.5x66m | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 |

| Φ4.7x74m | 4.7 | 74 | 4.0 | 4500 | 0.35-4.0 | 630 |

| Φ4.8x74m | 4.8 | 74 | 4.0 | 5000 | 0.396-3.96 | 630 |

| Φ5.0x74m | 5.0 | 74 | 4.0 | 6000 | 0.35-4.0 | 710 |

| Φ5.6x87m | 5.6 | 87 | 4.0 | 8000 | Max 4.23 | 800 |

| Φ6.0x95m | 6.0 | 95 | 4.0 | 10000 | Max 5.0 | 950*2 |

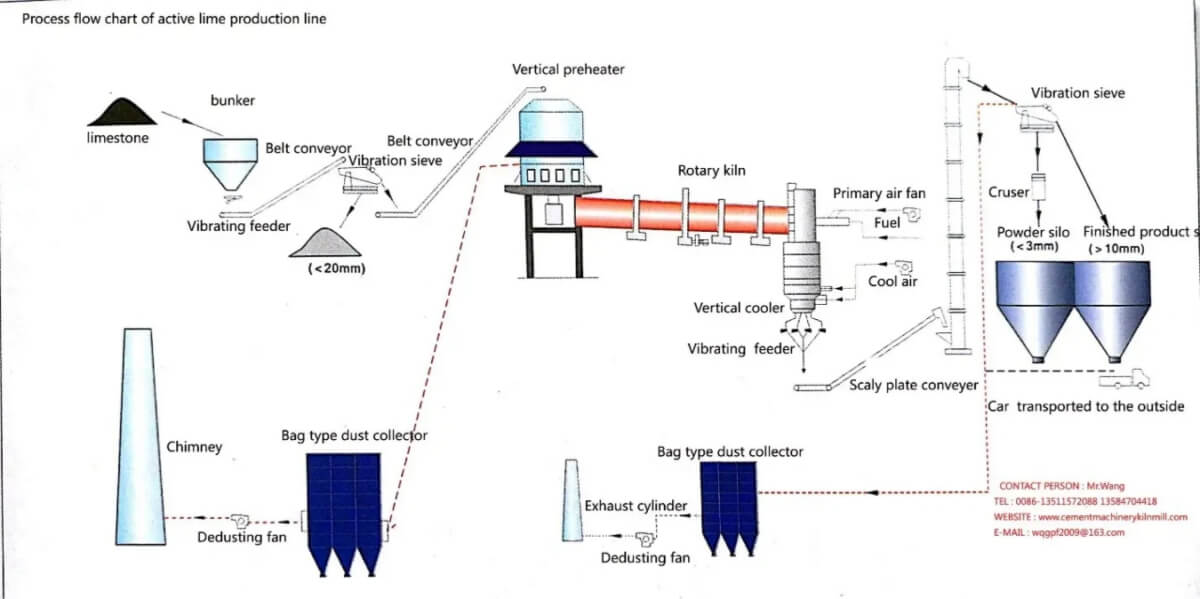

Process Flow Chart