Product Introduction

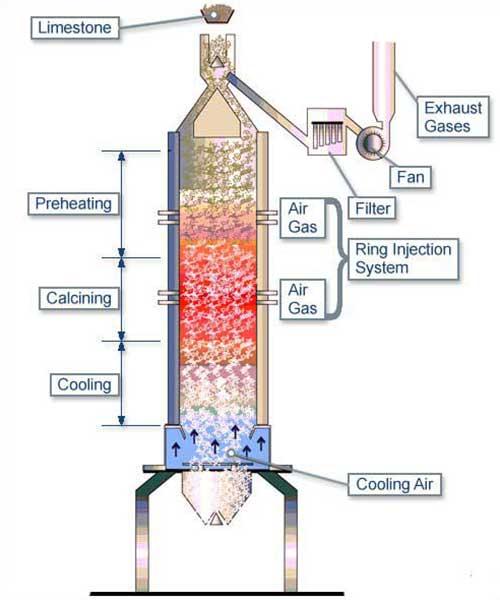

The vertical shaft kiln consists of a kiln body, a combustion chamber, a feeding device, a discharging device, etc. The kiln body is equipped with a refractory lining and a multi-layer grate.

Materials are added from the top of the kiln, fall layer by layer under the action of gravity, and are discharged from the bottom of the kiln after preheating, calcination, cooling and other stages. The working principle of the vertical kiln is that materials fall layer by layer under the action of gravity, and the calcination process is completed through preheating, calcination, cooling and other stages. The fuel burns in the combustion chamber to produce high-temperature flue gas, and the flue gas passes through the multi-layer grate to preheat and calcine the materials. The preheated materials fall into the next layer of grates for calcination, and this is done layer by layer until the materials are discharged from the bottom of the kiln.

Product Advantages

01.

The kiln operation is highly flexible and can be adjusted arbitrarily from 60-100% to achieve stable production;

02.

The equipment has a simple structure and a small footprint;

03.

Low investment and maintenance costs;

04.

Low heat consumption and reasonable utilization of heat energy. The secondary high-temperature air preheated by cooling lime directly participates in combustion.

Application Scope

Suitable for metallurgy, building materials, calcium carbide, nano calcium carbonate, aerated concrete, sugar and other industries.

Main Technical Specifications

| Model | Capacity(t/d) | Kiln Inner Diameter/m | Kiln Outer Diameter/m | Calcination Temperature/℃ | Grain Size | Overburning/Underburning Rate |

| ∅3.5*19.5m | 150 | ∅3.5 | ∅5.4 | 1000-1200 | 40-80 | ≤5% |

| ∅4.0*22m | 200 | ∅4 | ∅5.9 | 1000-1200 | 40-80 | ≤5% |

| ∅5.3*26.5m | 350-400 | ∅5.3 | ∅7.2 | 1000-1200 | 40-80 | ≤5% |

| ∅5.8*29.5m | 450-500 | ∅5.8 | ∅7.8 | 1000-1200 | 40-80 | ≤5% |

Process Flow Chart