Product Introduction

The extrusion hole diameter is generally 8-16mm, the granulation is 1-15 tons per hour, and the installed power is 7.5-30 kilowatts, which can meet the granulation needs of a variety of materials.

Product Advantages

01.

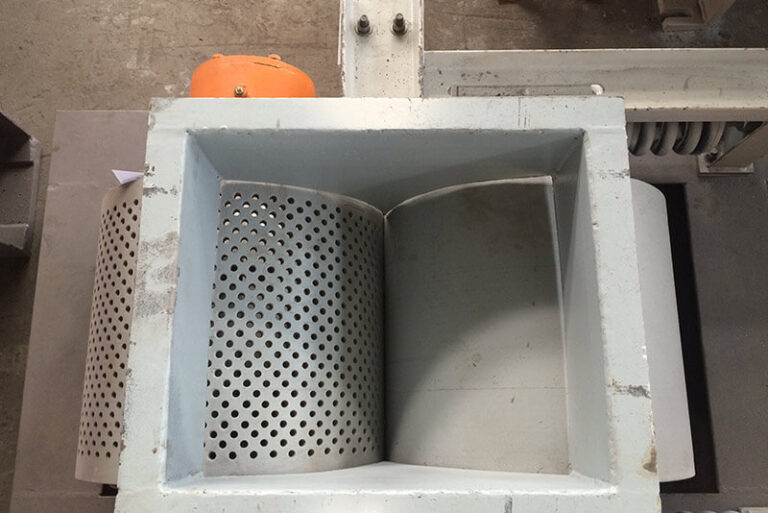

This type of double-roller granulator developed for the calcination characteristics of ceramsite, with advanced technology and stable quality;

02.

High production efficiency and high balling rate;

03.

The material is discharged uniformly. The ceramsite produced by this double-roller granulator is uniform in size and can meet the requirements of the ceramsite rotary kiln on the size and shape of the balls;

04.

The overall operation of the equipment is stable with low noise. At the same time, the sealing cover is used to receive materials. The work site is clean and tidy, which reduces the labor intensity of workers.

Application Scope

Roller granulators are widely used in chemical, petrochemical, building materials, mining and metallurgy, environmental protection and other industries. Applicable materials include sludge, bauxite, coal powder, limestone, coal gangue, clay, shale, etc.

Main Technical Specifications

| Model | Diameter(mm) | Length(mm) | Aperture(mm) | Speed(r/min) | Capacity(t/h) | Installed Capacity(kW) |

| GL450×400 | Ф450 | 400 | 8-16 | 58 | 2~5 | 11 |

| GL610×700 | Ф610 | 700 | 8-16 | 40 | 5~8 | 18.5 |

| GL700×600 | Ф700 | 600 | 8-16 | 36 | 5~8 | 18.5 |

| GL800×700 | Ф800 | 700 | 8-16 | 30 | 8~12 | 18.5 |

| GL1000×900 | Ф1000 | 900 | 8-16 | 26.4 | 10~15 | 30 |