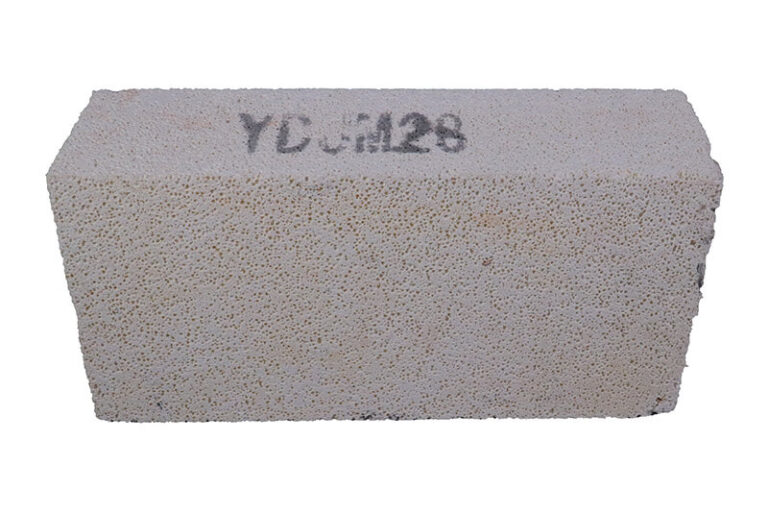

Product Overview

Mullite insulation brick is made from mullite as main crystal phase, the alumina content is between 40~70%, it is a kind of high alumina refractory. Except mullite, lower alumina content mullite insulation brick also has a small amount of glass phase and cristobalite. The advantage of mullite lightweight insulation brick is that it can be exposed to flames and used directly in high temperature furnace linings. Mullite light weight insulation brick is a refractory insulation material widely used in emerging industrial furnaces and high temperature equipment.

Classification by refractoriness: JM23, JM26, JM28, JM30, JM32.

Product Characteristics

01.

Higher refractoriness under load

02.

Good chemical erosion resistance

03.

High mechanical intensity and long service life

04.

Good thermal shock stability

05.

Low thermal conductivity and good thermal insulation effect

Application

Mullite insulation brick is popular in hot blast stove crown, flame side and bottome parts, glass melting kiln, ceramic kiln, petroleum cracking system corners and linings, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shuttle kilns, etc.

Specification should be different according to different furnaces/kilns, standard shapes and customized drawings are acceptable.

Product Specifications

| Item | JM23 | JM26 | JM28 | JM30 | JM32 |

| Al2O3(%) | 37 | 54 | 64 | 72 | 77 |

| Fe2O3(%) | 1.0 | 0.9 | 0.8 | 0.7 | 0.5 |

| Classification Temp.(℃) | 1260 | 1430 | 1540 | 1650 | 1760 |

| Bulk Density(g/cm3) | 0.58 | 0.78 | 0.88 | 1.03 | 1.25 |

| Cold Crushing Strength Mpa | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 |

| Thermal Expansion 1000℃(%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 |