Product Introduction:

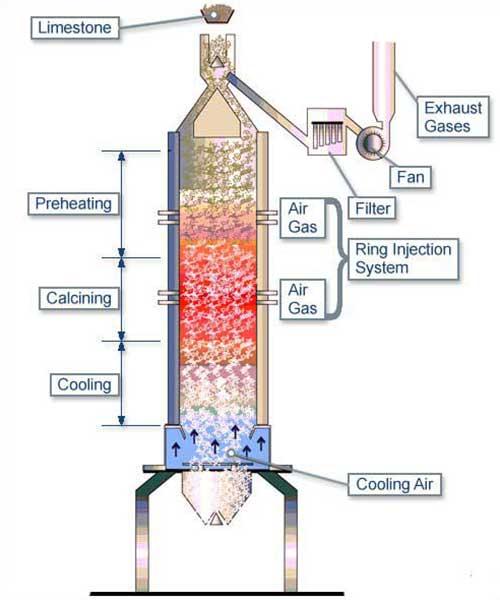

The vertical shaft lime kiln is an upright kiln used for burning lime. It is an upright cylinder equipment with an all-steel structure. It uses the principle of heat exchange between the downward movement of the material under its own weight and the upward movement of the hot gas to burn limestone. Materials are added from the top of the kiln and discharged from the bottom of the kiln after calcination. According to the temperature changes and distribution in the shaft kiln, it is divided into three zones from top to bottom: preheat zone, calcination zone, and cooling zone.

In the preheat zone, materials are preheated with the heat of flue gas; in the calcination zone, the material is calcined with the heat released by fuel combustion; in the cooling zone, the calcined material exchanges heat with the blown cold air, the material itself is cooled, and the heated air enters the calcining zone as combustion-supporting air. In order to ensure that each stage of the material calcination process is fully and completely carried out, the three zones in the vertical kiln should be maintained at a certain height and strive to be stable. It adopts modern technology and can make full use of cheap energy, especially gases that originally polluted the environment (such as converter gas, blast furnace gas, calcium carbide furnace tail gas, etc.) as the main energy source, turning waste into treasure.

Product Advantages:

01

Energy saving: after the fuel burns and releases heat to calcine the material, the remaining hot flue gas enters the preheating zone to preheat the normal temperature material to the pre-decomposition temperature. The output flue gas temperature reduce to 170~300℃.

02

The kiln lining is made of four layers of refractory materials, which has good thermal insulation effect. The temperature of the kiln shell can be controlled at about 60°C higher than the ambient temperature, which can reduce the energy consumption.

03

Under normal circumstances, refractory materials can be used for a longer time of 6 to 10 years.

04

The fuel has wide adaptability. The mixed-fired kiln can use lump coal and coke; the gas-fired kiln can use high calorific value fuels such as natural gas, coke oven gas, petroleum gas, and can also use converter gas, blast furnace gas, calcium carbide furnace tail gas, and blue charcoal. Low calorific value fuels such as coal gas and generator gas; oil-burning kilns can use liquid fuels such as heavy oil and diesel.

05

Due to the vertical arrangement of the shaft kiln, the large-angle arrangement of the single bucket elevator for feeding materials, and the compact layout of each functional area, the area is reduced;

06

Lower investment, the kiln steel structure has fewer machined parts and lower processing costs; it is easy to install and build refractory materials.

Main Technical Specifications:

| Capacity (t/d) | 100 | 150 | 200 | 300 | 400 |

| Distributor | BL-2 | BL-2 | BL-3 | BL-3 | BL-4V |

| Vertical Kiln | 150m³ | 200m³ | 250m³ | 400m³ | 500m³ |

| Calcination. Temp/ | |||||

| Energy Consumption Index /(kCal/kg Lime) | |||||

| Power Consumption Index /(kW·h/t Lime) | |||||

| Light & Over Burnt Rate /% | ≤13 | ||||

| Lime Activity /ml | 220~280(depends on the composition of limestone) | ||||

| Lime Discharging Temperature /℃ | Ambient Temperature+60 | ||||

| Limestone Feeding Size /mm | 30~80/80~120 | ||||

| Working Days / Days Per Year | ≥340 | ||||

| Fuel Type | Coal Powder, natural gas, lump petroleum coke, biomass fuel, etc. | ||||

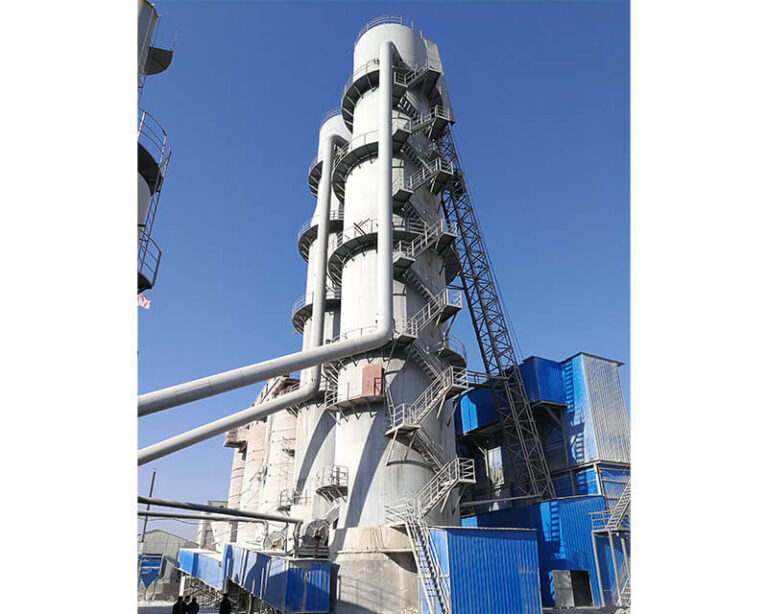

Process Flow Chart: